The ideal gelation temperature

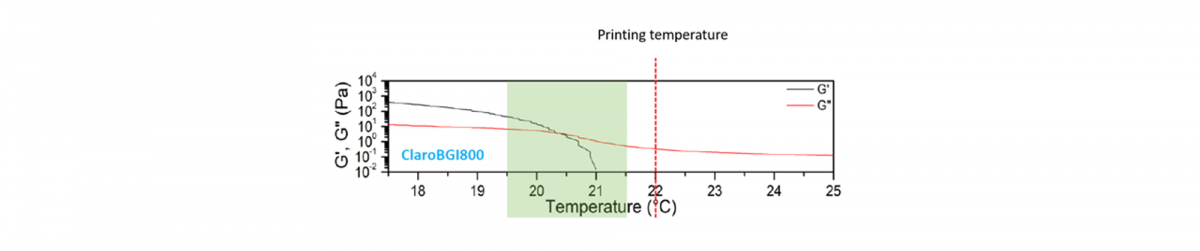

Gelation temperature (Tgel) and printing settings (e.g. printing speed and nozzle gauge) are influenced by two controllable variables: gelatin methacryloyl (GelMA) concentration and the degree of functionalization (DoF). Higher hydrogel concentrations combined with low DoF will result in higher Tgel. Thermo-sensitive materials, such as GelMA, require printing temperatures of around 2-5°C above Tgel. Materials with a low Tgel (<20°C) present low viscosity at ambient conditions and require a higher nozzle gauge (narrower diameter of opening) to print. They are normally recognized as high translational speed materials for printing.

ClaroBGI800 is a gelatin-based bio-ink modified with methacryloyl groups (DoF ~ 80%), it shows a Tgel of 20-21 °C when used to prepare a hydrogel at 10% w/w. Smooth printing behavior is observed for up to 2 hours at ambient conditions (T = 22 °C) using nozzle gauge 27G.

Want to empower the flow of your research? Connect with us via flow@claro.science